How Important is Incubator Monitoring for laboratories and other life science uses?

Incubators are used in all sorts of research and manufacturing processes, such as pharmaceuticals, microbiology, and biotechnology. These specialised chambers maintain the exact conditions required for microbes, cell cultures and other highly sensitive uses. Keeping the incubators at constant temperature, humidity and CO2 levels is critical to maintaining the integrity of research and outcome effectiveness. Deviations of one tenth of a millimeter can have a big bearing on the outcome, and constant monitoring is a critical component of lab life.

Dickson incubator monitoring solutions offer unparalleled accuracy and reassurance. Leveraging cutting-edge technology, Dickson makes it easier for laboratories and production facilities to meet high-level standards within the industry, including FDA 21 CFR Part 11, GLP and GMP. These solutions not only protect high-priority experiments but also keep laboratories audit-ready and compliant with regulations.

Meet Compliance Requirements

Dickson Takes Care of Your Lab Incubator Monitoring Concerns

Our temperature and humidity monitoring systems ensure you can confidently meet even the most stringent compliance needs. With over 100 years of experience and leading-edge technology, Dickson delivers peace of mind with quality and reliability of proven monitoring solutions.

Real-Time Monitoring

With real-time monitoring across multiple points, our environmental monitoring solutions can alert you if any sensor detects significant temperature excursions, disconnects, or device failures. Whether email, SMS/text, or phone call, receive alerts how and when you want so that corrective actions can be taken quickly to prevent loss.

Accurate Calibration

Over time sensors need regular calibration as they gradually lose pinpoint accuracy due to natural wear and tear. This can lead to a false sense of security, placing products at risk and creating unnecessary alarms. With Dickson's on-site ISO/IEC 17025 accredited lab, you get accurate calibration traceable back to Malaysia standards to ensure you remain compliant.

Scale Easily

Whether it's a thousand sensors or multiple facilities and locations, our incubator monitoring systems are built to scale so you spend less time monitoring and more time being productive. With OCEAView, you can view all your devices and settings in a single location and manage and configure devices consistently.

Compliance

With comprehensive dashboard and reporting capabilities, Dickson takes the guesswork out of alarm reporting. From the OCEAView dashboard, you can centralize and create custom, robust reports that leverage compliance features and log audits for proof of performance.

End-to-end Monitoring

Our Solution Delivers on All Aspects of Compliance

Advanced Technology with the OCEAView Platform

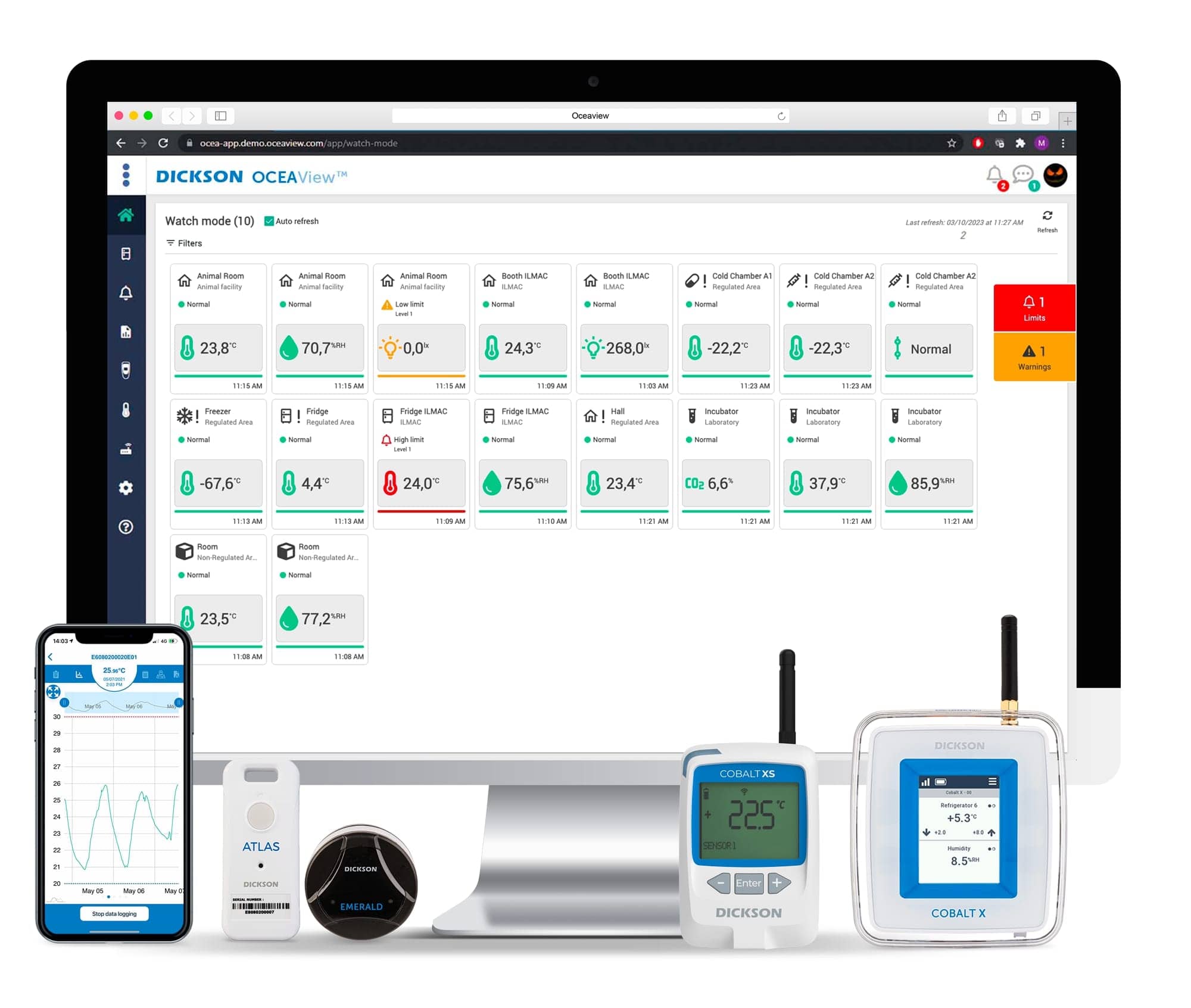

OCEAVIew provides the core of Dickson's incubator monitoring offerings. This cloud-based platform gives real-time monitoring of key parameters to keep incubators at their best. The platform lets you see data from anywhere, monitor patterns, and act on deviation early enough to keep things running.

Highlights of the OCEAView platform include:

-

- Individually configurable Alerts: Real-time alerts of temperature, humidity and CO2 changes.

-

- Integrity: Secure data storage with audit trails to adhere to compliance requirements.

-

- Remote or on-premise access: User-friendly web and mobile dashboards let users remotely inspect incubators any time of day or night.

-

- Modularity: You can easily scale the system to control multiple incubators at different facilities.

By working in conjunction with Dickson's precision sensors and data loggers, the OCEAVIew platform provides comprehensive, reliable incubator monitoring.

Solution & Process

How Our Solution Works

1

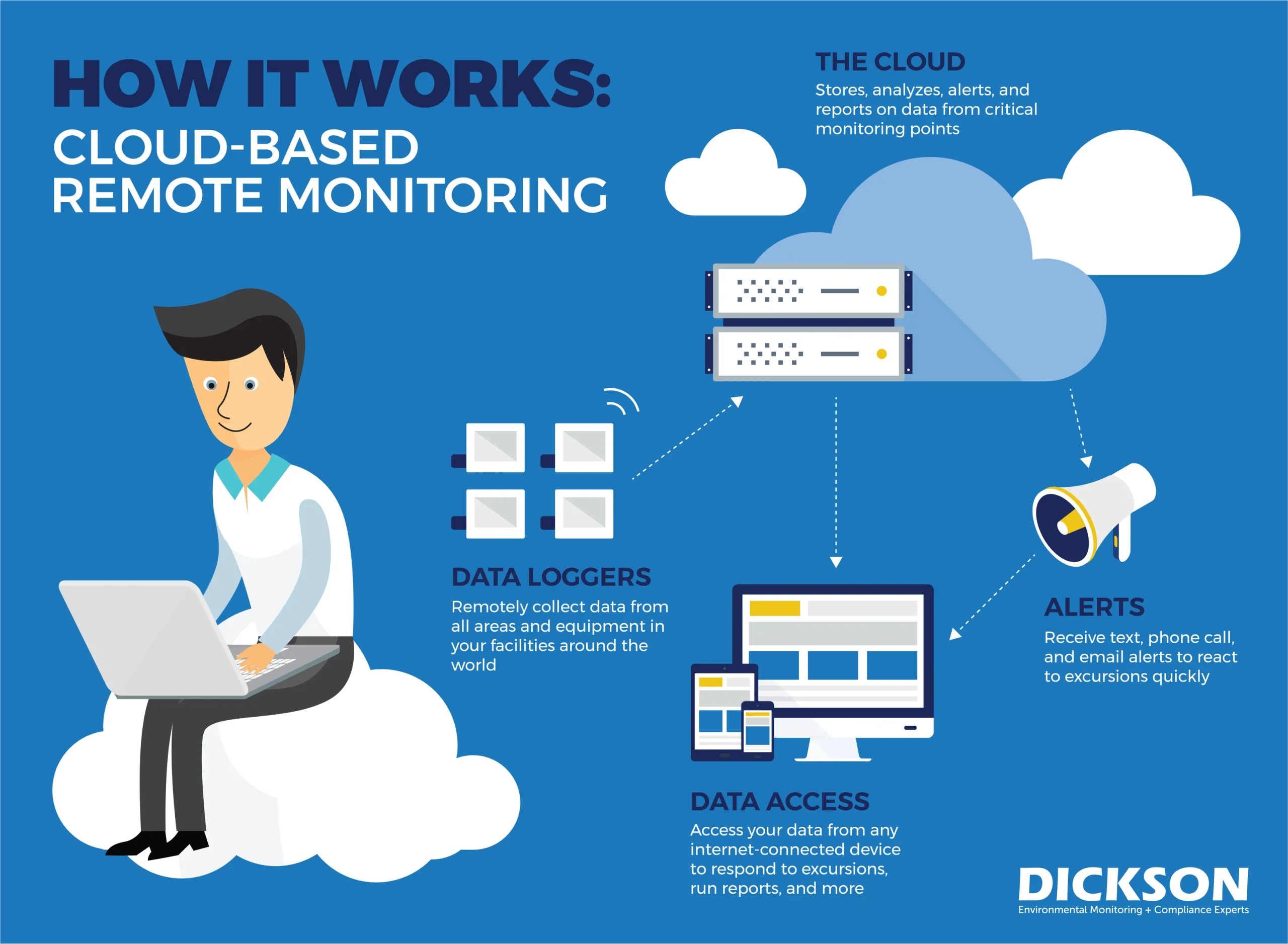

Sensors & Data Loggers

Intelligent sensors with NF EN ISO/IEC 17025-traceable calibration applied to incubators allow remote monitoring of temperature and humidity to protect your experiments and comply with regulatory requirements.

2

Cloud Monitoring

Data loggers collect temperature and humidity data and automatically deliver it to our cloud-based, remote incubator monitoring system, OCEAView, so you can monitor essential data anytime, anywhere.

3

Compliance Reporting

OCEAView's intuitive dashboard displays all critical tracking information on a single screen, giving users an easy way to access real-time status, audit trails, and compliance reports. Effortlessly create customized, automated reports for compliance reporting.

4

Real-Time Alerts

Create tailored alarm notifications (phone call, SMS, email, etc.) to alert users so they can take corrective action to protect your experiments. Set up alerts for multiple warnings and excursions, high/low variable readings, and device failures or disconnects.

Temperature, Humidity & CO2 monitoring

Incubator Precision Sensors and Dataloggers

Dickson's sensors and dataloggers are designed specifically for incubator monitoring. They're precision instruments that measure temperature, humidity and CO2 to give scientists the kind of data they need to keep experiments under strict surveillance.

-

- Temperature Sensors: Provide accurate temperature measurements to keep the incubator in a normal state.

-

- CO2 Sensors: Essential for cell culture and microbial expansion applications.

-

- Humidity sensors: To keep moisture at the right level, so as to avoid desiccation or condensation.

Every device is connected to the OCEAView platform for centralized reporting and real-time monitoring. Dickson's products are built for reliability and durability, which gives them the capability to function reliably in a high-use environment.

Dickson,'s range of sensors also include the innovative triple Smart-Sensor: a compact and accurate device that continually measures temperature, relative humidity, and carbon dioxide concentration inside incubators to help ensure stable conditions and provide optimal control of the culture environment.

Industry Leading Solutions

We've Got the Right Features for Incubator Monitoring

Every test and case is different. From real-time notifications, to permanent monitoring, and accurate reports, Dickson's environmental monitoring solutions give you the peace of mind that your cultures are growing as intended. We here at Dickson know that keeping tabs on the environment in an incubator is important to the efficiency of your lab experiments and procedures. We develop a laboratory temperature monitoring solution that can address the needs of incubator monitoring in many different scenarios such as vaccine development, tissue engineering, cell and gene therapy, etc.

Useful Information & Best Practice

We Are Serious About Incubator Monitoring

How to Maximize Incubator Monitoring

To have an incubator monitoring system that works properly, you must take it seriously. Here are some best practices to think about:

- Thresholds and Warnings: Establish safe ranges of temperature, humidity and CO2 levels and set alarms to alert workers when they deviate from those values in real time.

- Schedule Routine Maintenance: Inspect and test sensors and dataloggers regularly to keep them performing at optimum levels.

- Analyze Historical Data: Apply data analysis to detect trends and threats to streamline business processes.

- Training Lab Personnel: Train lab staff on how to operate monitors and handle alerts.

Integrate Monitoring across Systems: Collect data across multiple incubators into a single system for easier analysis and reporting.

These techniques allow labs to fine-tune their incubator operation, reduce risk and yield reproducible outcomes.

How Physical Parameters Matter in Incubators

Incubators use an exacting trade-off between physico-chemical factors, like temperature, humidity and CO2, to establish optimal conditions for cell cultures and microbes. Variation of these values can compromise the quality of samples, compromising research or production. Temperature changes, for example, can change enzyme activity, cellular metabolism, and microbial proliferation, which will tip the experiments out of proportion or turn a batch useless. Real-time monitoring of these parameters allows labs to spot a deviation before it develops and take action to keep things optimal.

Keeping environmental variables tightly controlled is vital not only for the safety of regulation, but also for the reproducibility of scientific experiments. Scientists rely on predictable incubator results to generate repeatable yields. With automated monitoring solutions leveraging the latest analytics, it is now possible to reduce risk and ensure quality control across the research and production environments.

Effects of Incubator Parameter Differences on Safety Factors

Physical abnormalities within incubators can create severe problems. For instance, a small temperature drop can inhibit microbial growth and push back manufacturing cycles in biopharmaceutical manufacturing. In contrast, high CO2 can alter pH in cell cultures and impair cellular function and survival. These problems can be catastrophic when designing vaccines, where accurate conditions are essential for efficacy and safety.

In microbiology labs, excessive humidity results in condensation, which may ruin cultures or interfere with experimental designs. Likewise, low humidity can dry out samples, degrading their integrity. Each of these scenarios highlights the necessity of real-time monitoring in order to avoid costly mistakes and ensure research integrity. Dickson's products are built to address these issues, giving labs the means to operate at optimum levels throughout.

The Advantages of Wireless Data Loggers in Incubator Monitoring

Wireless data loggers to monitor incubators have changed the way labs work by making the process easier, more accurate and more secure. As compared to conventional monitoring techniques, wireless systems require no manual data entry and save valuable lab time from human error. Wireless data loggers automatically send readings to centralized databases such as OCEAView, which gives you up-to-the-minute incubator monitoring wherever you are.

A further advantage of wireless data loggers is that they will maintain unimpeded monitoring even when the network fails. High-end models cache information locally and sync as soon as connectivity re-establishes, ensuring that you never lose important data. This is especially useful for labs that have strict compliance standards and need to keep records.

By delivering scalable solutions that can be easily integrated into existing systems, wireless data loggers make monitoring multiple incubators in large-scale facilities easier. Their intuitive user interfaces and robust analytics enable laboratory managers to make decisions, automate processes, and rest assured that their monitoring infrastructure will not let them down.

Designed to Meet Your Needs

Lab Incubator Monitoring-Related Products

Explore our range of products below to find the latest in temperature control, cold chain tracking, and other top quality instruments customized to fit your monitoring needs.

Cobalt X Data Logger

Color touchscreen data logger with LoRaWAN® and Bluetooth® wireless connectivity, supporting up to four simultaneous wired and/or wireless sensors. Fully integrated with OCEAView.

Cobalt X data loggers support up to 4 external sensors simultaneously to monitor your invaluable equipment. Readings are recorded in on-board memory, then transmitted to the OCEAView remote monitoring solution via LoRaWAN or Bluetooth Low Energy connectivity. Cobalt X offers interactive touch screen controls and highly visible alert indicators, with support for a wide variety of environmental sensors, including our Bluetooth enabled remote sensors.

Cobalt XS Data Logger

Ideal for life science, agri-food, and logistics sectors, Cobalt XS gives you a cost-effective and reliable way to keep an eye on the environmental parameters of your sensitive assets, storage facilities, products, equipment, and more.

The Cobalt XS data logger implements LoRaWAN wireless connectivity to provide very long-range coverage to minimize your related on-site infrastructure requirements.

Dickson’s Smart-Sensor technology makes maintenance easier by storing all calibration information directly in the sensor, providing both high accuracy and on-the-fly sensor swapping for recalibration.

Ready to chat?

Talk to a Specialist About Your Incubator Monitoring Needs

Our trained team of professionals is ready to help you through the compliance process from start to finish. Reach out today to start the conversation. Call +1 (630) 543-3747 or send us a message.