Monitor & Control your Environmental Parameters

Ensuring Optimal Freezer Temperature Conditions Across Industries

A Freezer Monitoring System is critical for industries storing temperature-sensitive goods in freezers, especially at ultra-low temperatures. Whether you're managing clinical trials, vaccine storage, or frozen food inventory, the risk of temperature excursions is real - and expensive.

With Dickson's industry-leading data loggers and compliance services, you get a robust, scalable solution that ensures real-time visibility, automated alerts, and full audit readiness.

Since 1923, Dickson Data has been an industry innovator and leader by changing the way organizations monitor their temperature, humidity, and pressure-controlled environments.

Industries that rely on Dickson's Freeze Monitoring Solutions:

- Pharma & Biotech: Vaccine storage, clinical trial monitoring, biologic sample protection

- Healthcare & Labs: Blood, plasma, tissue samples, research-grade freezers

- Food & Beverage: Commercial freezer compliance with food safety protocols

- Manufacturing & Logistics: Cold chain validation and asset traceability

The Dickson Advantage

Important Considerations for Freezer Monitoring

Real-Time Freezer Monitoring with the OCEAView Platform

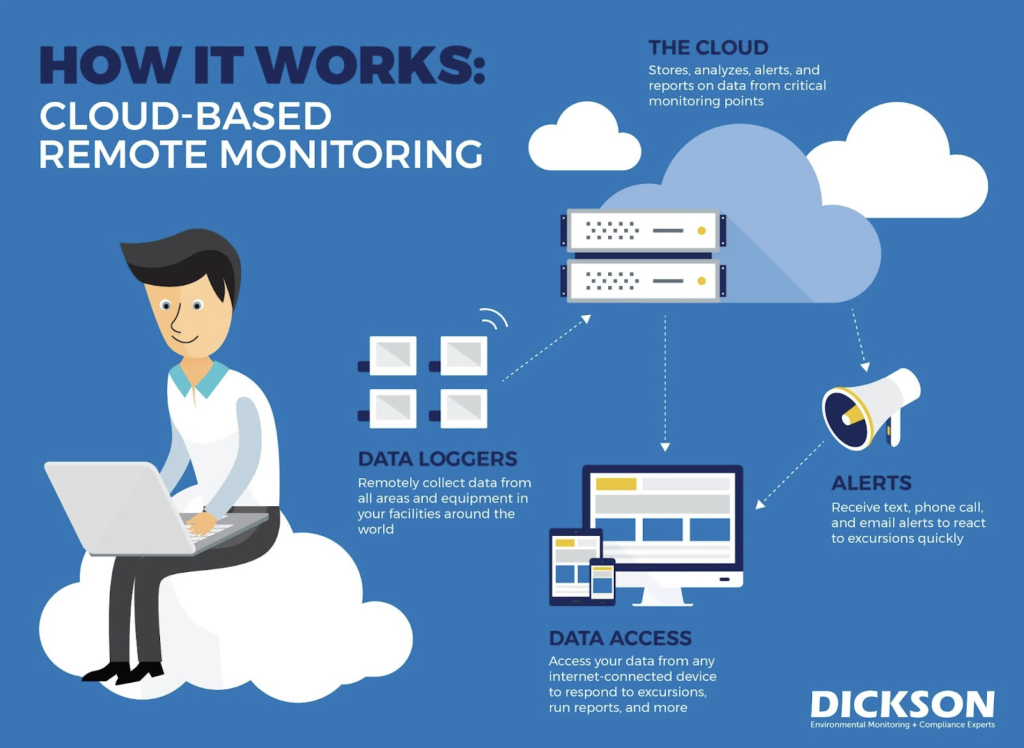

A cornerstone of Dickson's freezer monitoring solutions is the innovative OCEAView platform. This cloud-based system delivers real-time temperature monitoring and alerts, enabling organizations to maintain strict control over one or multiple freezer units - from commercial freezers to ultra-low temperature (ULT) storage - with unmatched ease and visibility.

OCEAView's user-friendly interface allows users to track temperature trends, set custom alert thresholds, and receive instant notifications if conditions deviate from acceptable ranges. This rapid response capability is essential for protecting temperature-sensitive inventory such as vaccines, biologics, or frozen food products. The platform's wireless connectivity options (Wi-Fi, Ethernet, or LoRaWAN) simplify installation and allow for scalable deployments without the need for complex infrastructure.

By securely storing data in the cloud, OCEAView supports full compliance with regulations like FDA 21 CFR Part 11 and GxP. It ensures tamper-proof records, enables effortless report generation, and keeps organizations audit-ready with accurate, accessible temperature logs - even across multiple storage sites.

Reliable & Safe Solutions

Key Advantages of Dickson's Freezer Monitoring System

We understand your needs

Ready to Upgrade Your Freezer Monitoring?

Whether you're monitoring a single ULT freezer or managing hundreds across facilities, Dickson offers turnkey solutions that combine hardware, software, and expert support. Book a demo or contact Dickson's compliance experts to design a system tailored to your operational and regulatory needs.

The best solutions

Precision Monitoring Solutions for Freezer Environments

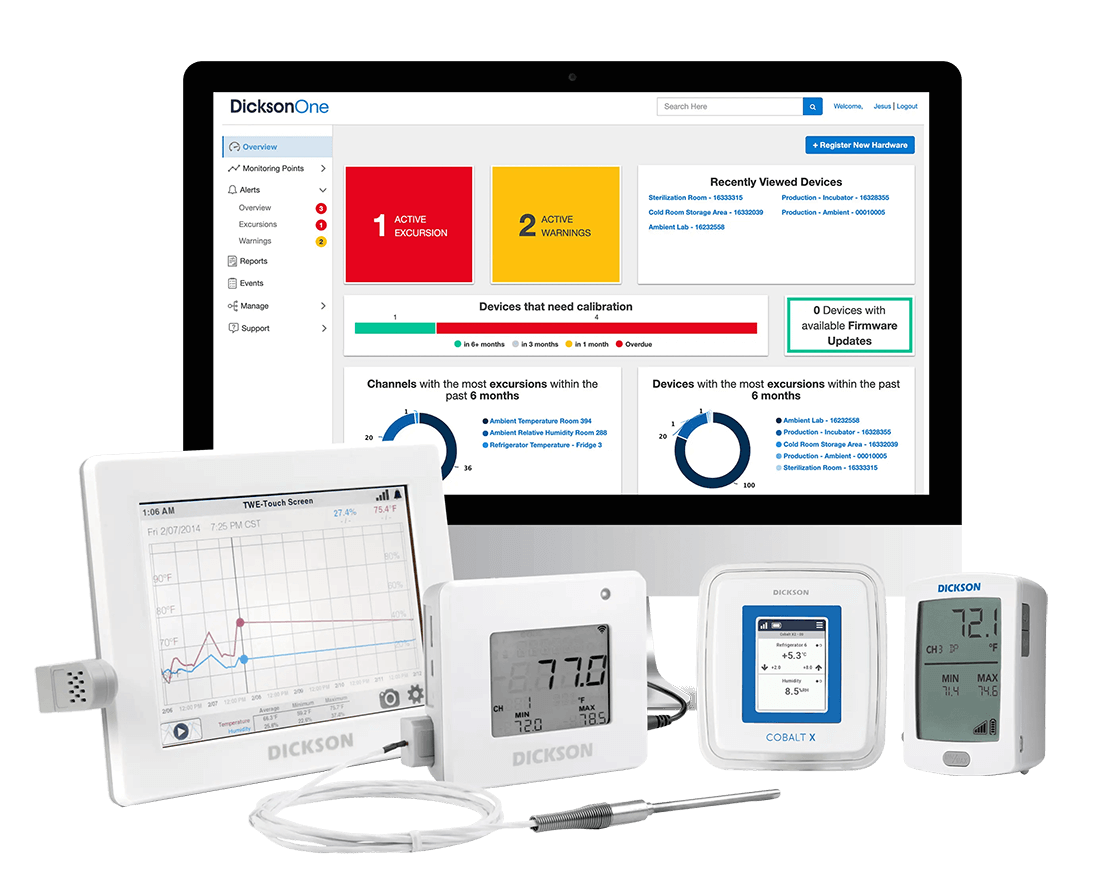

To complement the DicksonOne platform, Dickson offers a comprehensive range of high-precision sensors and data loggers designed specifically for freezer environments. These devices ensure accurate and reliable monitoring of critical parameters, which is essential for maintaining compliance and operational efficiency.

One standout offering is the Pt100 Smart-Sensor, ideal for monitoring ultra-low temperature freezers, including cryogenic storage and liquid nitrogen tanks. Maintaining precise temperature control is crucial to preserving the integrity of temperature-sensitive products. The sensor's accuracy and compatibility with the DicksonOne platform make it a vital component of any comprehensive freezer monitoring system.

In addition to temperature sensors, Dickson provides data loggers capable of recording temperature and humidity with unparalleled precision. These devices are built to withstand the stringent demands of freezer environments while delivering consistent performance over time. Their compact designs and wireless capabilities make them easy to deploy and integrate into existing systems, ensuring seamless operation without compromising the integrity of freezer conditions.

By storing data securely in the cloud, DicksonOne ensures compliance with data integrity regulations such as FDA 21 CFR Part 11. This capability allows organizations to maintain detailed audit trails, generate reports effortlessly, and ensure that their operations are always inspection-ready.

Cobalt X Data Logger

Color touchscreen data logger with LoRaWAN® and Bluetooth® wireless connectivity, supporting up to four simultaneous wired and/or wireless sensors. Fully integrated with OCEAView.

Cobalt X data loggers support up to 4 external sensors simultaneously to monitor your invaluable equipment. Readings are recorded in on-board memory, then transmitted to the OCEAView remote monitoring solution via LoRaWAN or Bluetooth Low Energy connectivity. Cobalt X offers interactive touch screen controls and highly visible alert indicators, with support for a wide variety of environmental sensors, including our Bluetooth enabled remote sensors.

Cobalt XS Data Logger

Ideal for life science, agri-food, and logistics sectors, Cobalt XS gives you a cost-effective and reliable way to keep an eye on the environmental parameters of your sensitive assets, storage facilities, products, equipment, and more.

The Cobalt XS data logger implements LoRaWAN wireless connectivity to provide very long-range coverage to minimize your related on-site infrastructure requirements.

Dickson’s Smart-Sensor technology makes maintenance easier by storing all calibration information directly in the sensor, providing both high accuracy and on-the-fly sensor swapping for recalibration.

Pt100 Smart-Sensor -200°C to +50°C

Pt100 Smart-Sensor (-200°C to +50°C) for cryogenic freezers, Nitrogen tanks. The Smart-Sensor technology allows for on-board calibration details and features analog/digital converter to simplify calibration.

- On-board calibration details

- For Cobalt X and Cobalt L3

- Calibration: ISO/IEC 17025, NIST traceable

Ready to chat?

Talk to a Specialist About Your Freezer Monitoring Needs

Our trained team of professionals is ready to help you through the compliance process from start to finish. Reach out today to start the conversation. Call +603 749 40758 or send us a message.